Tolerance Analysis: A Beginner’s Guide to Engineering Precision

No manufacturing process is perfect—there will always be some level of variation in the parts that roll off the production line. The key to ensuring those variations don’t become costly problems is understanding how they impact your final product. That’s where tolerance analysis comes in.

Tolerance analysis helps engineers and manufacturers predict, control, and optimize mechanical variation so that everything fits together and functions as intended. Whether you’re designing aerospace components, medical devices, or consumer electronics, tolerance analysis ensures that small dimensional variations don’t lead to big headaches down the road.

In this guide, we’ll break down what tolerance analysis is, why it’s important, and how to apply it effectively in your design and manufacturing process.

What is Tolerance Analysis?

At its core, tolerance analysis is all about understanding how small variations in part dimensions impact the fit, function, and performance of an assembly. No two manufactured parts are identical—every component has slight deviations due to machine capabilities, material properties, and environmental factors.

Tolerance analysis allows engineers to quantify those variations and determine whether an assembly will still work as intended—even when every part isn’t made to its exact nominal size.

Key Components of Tolerance Analysis:

- Nominal Dimension – The "perfect" design size, before manufacturing variation is factored in.

- Tolerance – The allowable range of variation around the nominal size.

Tolerance Stack-Up – The cumulative effect of individual part tolerances on an assembly. - Worst-Case & Statistical Analysis – Methods to evaluate how variations affect product performance.

By evaluating tolerances early in the design process, you can prevent costly manufacturing issues before they happen.

Why is Tolerance Analysis Important?

A bad tolerance strategy can lead to assembly failures, high production costs, excessive rework, and missed deadlines. But a good tolerance strategy helps manufacturers strike the right balance between quality, cost, and performance.

Common Issues Without Tolerance Analysis:

- Parts don’t fit together – Components that should align perfectly may have unexpected gaps or interferences.

- Expensive rework & scrap – Fixing problems after production leads to wasted time and money.

- Missed deadlines – Design revisions and manufacturing delays can push projects off schedule.

- Field failures & recalls – If a product fails due to poor tolerance management, warranty costs and reputation damage can skyrocket.

How Tolerance Analysis Helps:

- Reduces Manufacturing Costs – Avoids unnecessarily tight tolerances that increase production expenses.

- Ensures Fit & Function – Verifies that parts will assemble correctly without interference or excessive gaps.

- Improves Reliability – Minimizes performance failures due to dimensional variation.

- Optimizes Quality & Efficiency – Helps identify where tolerances can be relaxed to save costs without sacrificing functionality.

- Enhances Supplier Communication – Provides clear, standardized tolerance requirements to manufacturers.

Types of Tolerance Analysis

There are two main approaches to tolerance analysis, each suited for different scenarios.

Worst-Case Tolerance Analysis

- Assumes that all parts are made at their extreme tolerance limits.

- Guarantees that an assembly will function even in the worst possible manufacturing scenario.

- Used in high-risk industries like aerospace, medical devices, and automotive safety.

Often results in tight tolerances, which can drive up production costs.

Statistical Tolerance Analysis

- Uses probability and statistics to predict real-world variation.

- Recognizes that most parts fall within a normal distribution rather than at their extreme limits.

- Allows for looser tolerances, which can reduce manufacturing costs while maintaining quality.

- Ideal for high-volume production, where small variations can be managed effectively.

Most companies use a blend of both methods, tightening tolerances for critical components while optimizing others for cost savings.

How is Tolerance Analysis Performed?

1. Define Critical Features

Identify the dimensions that are most important to product performance and assembly.

2. Set Tolerance Limits

Assign GD&T (Geometric Dimensioning & Tolerancing) symbols to control size, form, orientation, and location based on standards like ASME Y14.5 or ISO GPS.

3. Perform Tolerance Stack-Up Calculations

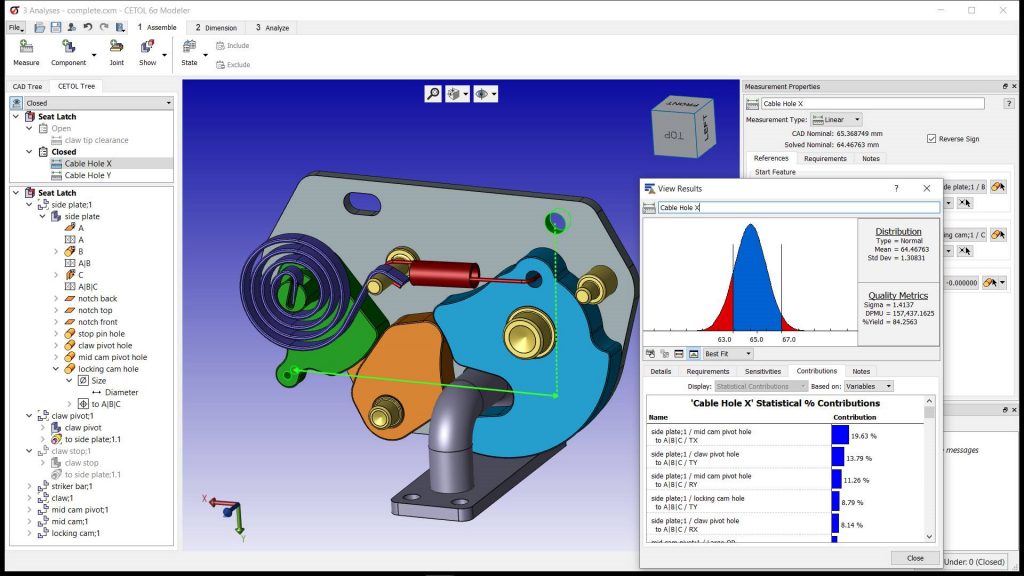

Manually calculate, use spreadsheets, or leverage advanced tolerance analysis software like Sigmetrix CETOL 6σ to analyze cumulative variation.

4. Evaluate Results & Identify Issues

Check for misalignment, excessive gaps, interferences, or assembly failures.

5. Optimize the Design

Adjust tolerances to balance cost, manufacturability, and performance.

Using Tolerance Analysis Software for Better Results

Manually performing tolerance analysis can be time-consuming, error-prone, and inefficient. That’s why leading companies use tolerance analysis software to streamline the process.

- Automates calculations, reducing human error.

- Integrates with CAD models, eliminating the need for manual data entry.

- Performs complex statistical analyses, providing more accurate predictions.

- Saves engineering time, speeding up design iterations.

Sigmetrix offers CETOL 6σ, EZtol, and GD&T Advisor, which provide engineers with precise, real-time tolerance insights.

Best Practices for Effective Tolerance Analysis

- Start Early – Perform tolerance analysis before production begins to prevent costly rework.

- Use GD&T Standards – Follow ASME Y14.5 or ISO GPS for consistent tolerancing.

- Balance Tolerance Tightness & Manufacturability – Avoid over-constraining parts unnecessarily.

- Leverage Statistical Methods – Use worst-case analysis for critical components, but apply statistical analysis where possible to reduce costs.

- Collaborate Across Teams – Work with design, manufacturing, and quality teams to ensure tolerances are practical.

- Use Software for Accuracy – Take advantage of CETOL 6σ and EZtol to optimize designs efficiently.

Final Thoughts: The Value of Tolerance Analysis

Tolerance analysis is an essential process for ensuring that products are manufacturable, cost-effective, and high-quality. By applying best practices and leveraging modern tools, companies can reduce costs, improve product reliability, and streamline production.

Whether you’re an engineer designing precision components or a manufacturer optimizing production, tolerance analysis gives you the confidence to build better products.

Ready to Take Your Tolerance Analysis to the Next Level?

Schedule a Demo Today! Discover how Sigmetrix software can help you achieve optimal tolerances, reduce costs, and streamline your design process.