Digital Insights to Master Variation Across Your Organization

VariSight is an enterprise mechanical variation management solution that centralizes CETOL model data, exposes measurements/sensitivities/contributions for analytics, and connects with your PLM to keep designs and analyses in sync. It helps teams see the impact of tolerance changes, compare predicted vs. actual results, and maintain full traceability across models, revisions, requirements, and users.

VariSight Quick Facts

- Who it’s for: Design, manufacturing, and quality leaders who need enterprise-wide control and visibility over tolerance analysis and mechanical variation.

- What it does: Stores and manages CETOL model data; imports inspection results; exposes measurements, sensitivities, contributions, and quality metrics for analysis and reporting.

- Integrations: Syncs with PLM to track CAD version history/assembly usage, query new revisions, and sustain end-to-end traceability.

- Analytics & decisions: Evaluate tolerance changes over time, run what-if comparisons, and generate comprehensive reports/dashboards for optimization.

- Traceability & governance: Link measurements to requirements, see aggregated pass/fail status, and track user-specific contributions and work history.

- How to get started: Request a guided demo; pair with instructor-led onboarding and implementation services for enterprise rollout.

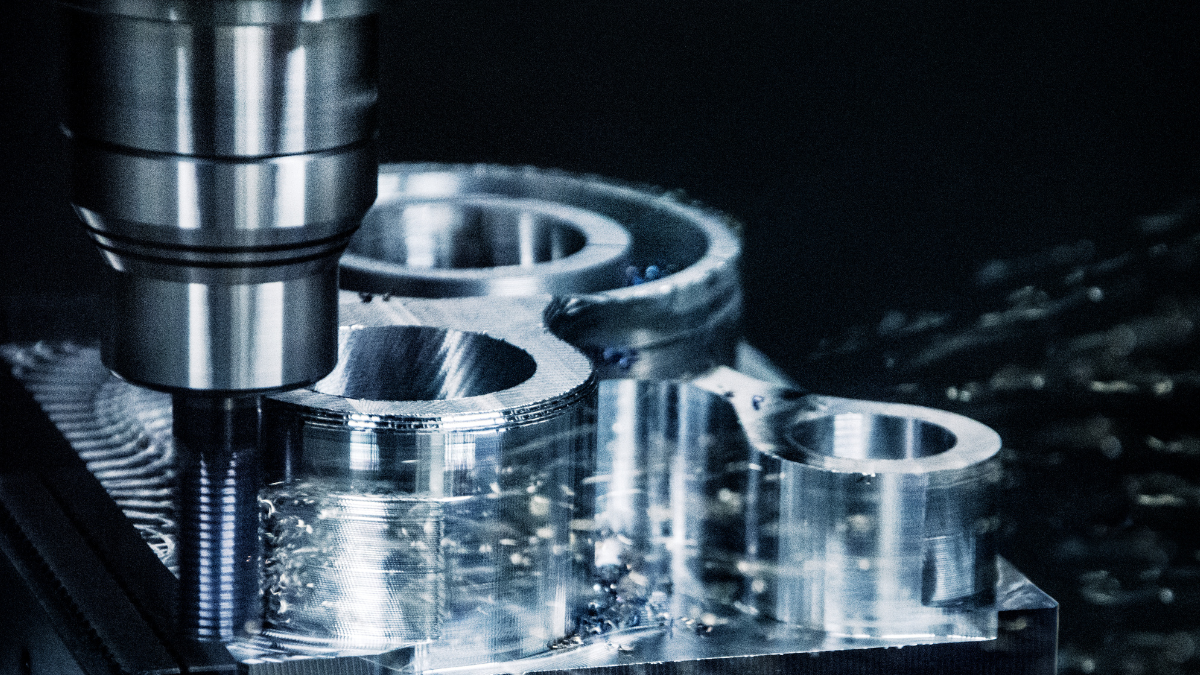

Streamlined Variation Management, Comprehensive Tolerance Analysis, & Advanced Insights for Decision-Making

Mechanical variation management helps minimize errors, optimize quality, and facilitate informed decision-making throughout the product development lifecycle. Without a comprehensive solution to store and expose variation elements, many organizations struggle to balance cost and quality.

VariSight is a comprehensive mechanical variation management solution, providing efficient storage and management of model data, exposing tolerance analysis elements for analytics, and seamlessly integrating with product lifecycle management (PLM) systems.

-

Store and manage CETOL model data, improving accessibility and organization of critical product information.

-

Expose tolerance analysis data like measurements, sensitivities, contributions, and quality metrics for comprehensive analytics.

-

Facilitate in-depth studies and comparisons through advanced model interrogation, ensuring traceability and synchronization with CAD model revisions.

-

Get robust traceability features, such as tracking user-specific contributions.

-

Plan and track tolerance analysis progress, enabling systematic linking of CETOL measurements to system requirements for detailed reporting on both historical analysis models and their aggregated statuses over time.

-

Report on requirements satisfied by measurements and their aggregated objective status (Pass/Fail) for improved quality control.

-

Evaluate the impact of tolerance changes, graphically visualizing measurement quality metrics over time.

-

Trace, search, and filter the work done on the tolerance model by a particular user or group of users.

Enterprise-Wide Mechanical Variation Management for Optimal Design Control & Traceability

Our revolutionary mechanical variation management solution drives efficiency with data storage, analytics exposure, and PLM integration.

Elevate Your Enterprise’s Mechanical Variation Management with Centralized Data Excellence

Empowering efficient mechanical variation management through comprehensive data storage, VariSight exposes tolerance analysis elements for analytics and advanced model interrogation.

-

Track the progress of all the tolerance analysis work needed to ensure a large volume of requirements and objectives are satisfied.

-

Identify which assemblies will be impacted, and how, if a tolerance on a part common to multiple assemblies is changed.

-

Easily evaluate iterations of an analysis model to understand what changed as both the design and analysis models evolve and the predicted quality of the requirements change.

-

Maintain traceability of the analysis models and corresponding results against the revisions of the CAD models in the PLM system.

-

Query the PLM system to identify when new revisions of a referenced model are available.

VariSight FAQs

You can evaluate the impact of tolerance changes over time, understand how assemblies are affected when a common part tolerance changes, and compare iterations as design and analysis evolve.

VariSight links CETOL measurements to requirements and reports aggregated objective status (e.g., pass/fail) for robust quality control and auditability.

Yes, traceability includes user-specific contribution tracking plus search and filtering by user or group across the tolerance model.

Introducing VariSight! Provide your email to receive exclusive VariSight updates straight to your inbox.

Our Full Suite of Software Products

Improve your products through mechanical variation management.

Expert-Led Product Training

Enterprise-Wide Implementation Services

Read More Mechanical Variation Resources

Experts weigh in on mechanical variation management in our array of blog posts.