Capture, Transfer, and Retain Critical Product and Process Knowledge

Share Complex Institutional Knowledge and Gain Operational Efficiency

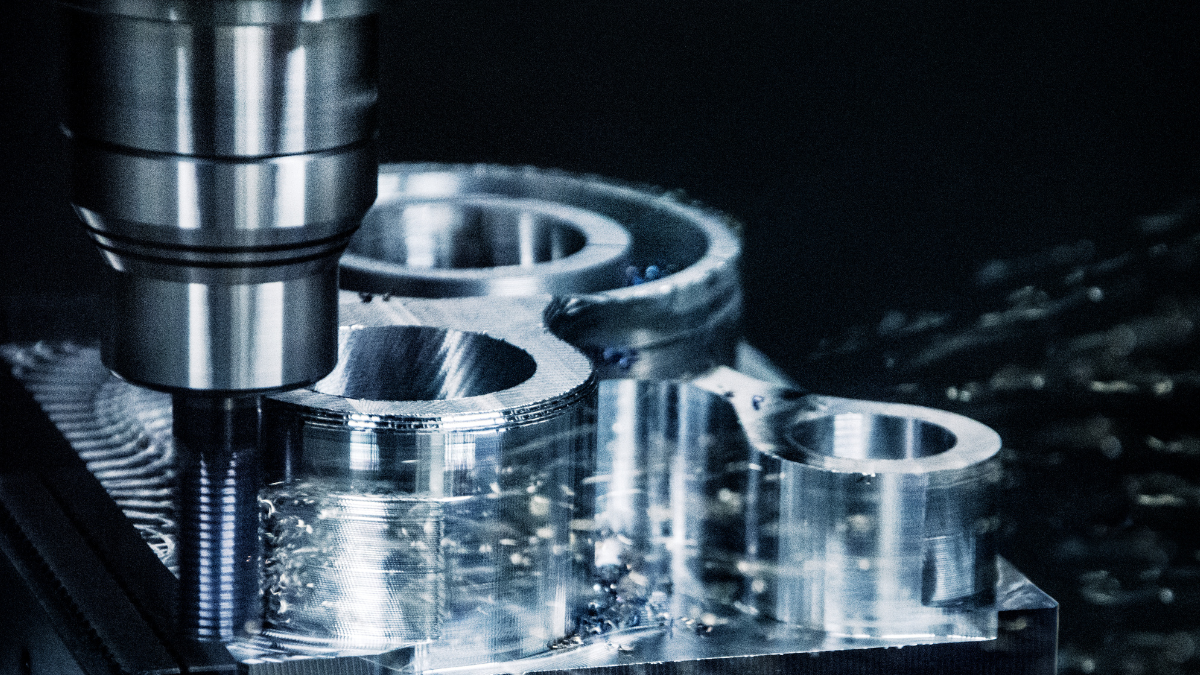

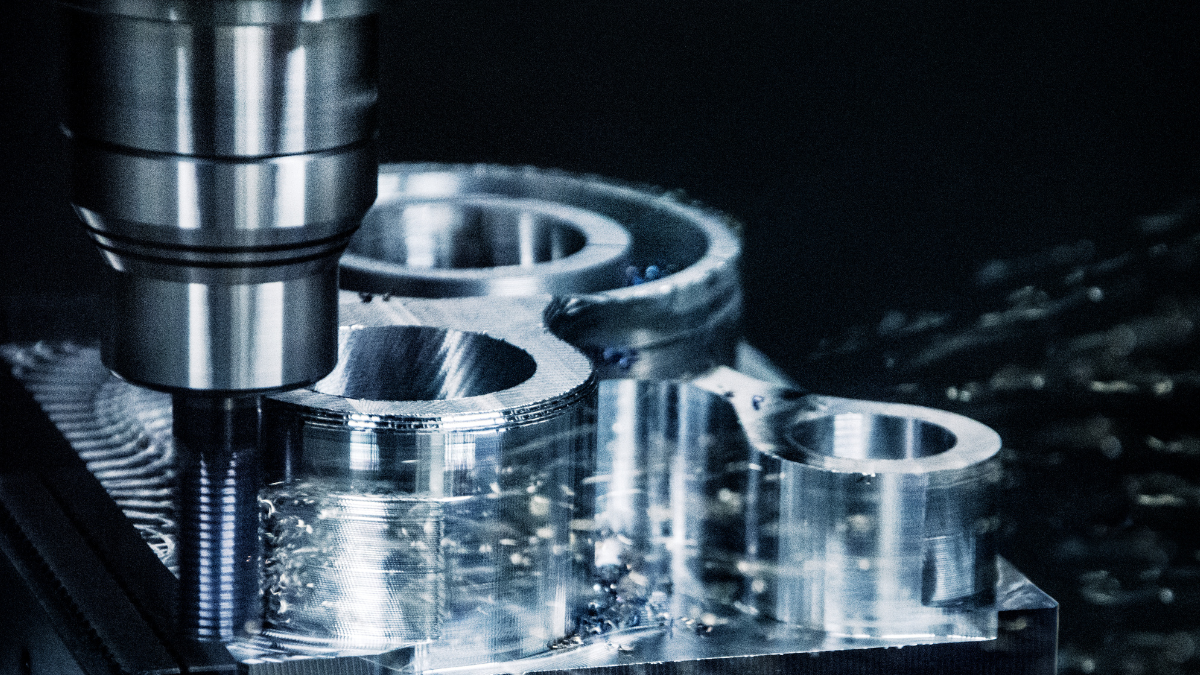

Your team has years of experience in their areas of expertise and your organization’s processes. But as experienced personnel leave, critical knowledge leaves with them, reducing the strength of your team. Who can answer questions about why certain tolerances were used on specific parts? Who teaches new hires about GD&T, tolerance stack-up, and internal manufacturing and assembly processes?

Moreover, who manages the complex legacy spreadsheets your team has been using to determine tolerance values?

The truth is, your organization’s products and processes cannot compete in the market if you don’t have a fast and easy way to gather critical product data for decision-making, share knowledge of complex products across the team, and transfer knowledge between employees and teams.

The solution? GD&T and tolerance analysis software and training from Sigmetrix.

Who We Help

-

Enable design engineers to work closely with manufacturing and assembly to compare concepts earlier in the design and prototyping processes.

-

Bring the full team up to the same level of understanding by democratizing the depth and breadth of product and process knowledge you share.

-

Make all of your data and insights easily accessible across departments, eliminating the time-intensive and costly design loops that result in wasted time and resources.

-

Enable a consistent, shared “language” among all teams, which extends to reporting standards—finally, all teams can work towards the same data-driven metrics.

How We Help

-

Lessen the impact of workforce attrition by sharing institutional knowledge in a common software, not a complex legacy spreadsheet or siloed digital environment.

-

Understand exactly why certain tolerances were used and avoid using products out of spec, a common misstep when teams lack understanding about historical product decisions.

-

Quickly and easily evaluate suppliers by comparing variation in acceptable tolerances—all in a shared environment that the full team can access.

-

Take advantage of comprehensive training in GD&T, tolerance analysis, MBD/MBE, and Sigmetrix software to ensure everyone is skilled in assessing complex design challenges and software implementation strategies.

Implement a Consistent Process for Managing Mechanical Variation

Gain efficiencies, ease of communication, competitive knowledge, and operational efficiency with GD&T and tolerance analysis software that unites your siloed teams.

With sophisticated tolerance analysis and GD&T software, use benchmark data to compare your company’s understanding of mechanical variation management and develop a comprehensive improvement plan. Make your manufacturing and assembly ideals a reality by controlling mechanical variation and reducing product cost. With our tolerance analysis software, CETOL, easily compare the impact of multiple suppliers’ variation in acceptable tolerance on your own assembly processes, ensuring robust product designs and high-quality outcomes.

Sigmetrix’s desktop and enterprise solutions have a familiar, easy-to-use interface and use consistent language with respect to design, manufacturing, and inspection in all products and services. Additionally, the full team will be used to a consistent GD&T language in all products and services, and training solutions will reinforce this improved standard of communication between design and manufacturing.

Everyone from subject matter experts to beginners can have access to mechanical variation modeling and proprietary processes, eliminating slowdowns at any level of the organization. All Sigmetrix tools (1D, 3D, and GD&T) have a consistent look and feel, meaning a concept can transition smoothly from roadmap to geometric dimensioning. Tolerance model data is closely linked to CAD model data so that it can be easily queried and accessed. Using the same tools means everyone speaks a consistent language with respect to design, manufacturing, and inspection across all products and services. With access to tolerance models for high-level “what if” studies, management can ideate without needing intervention from production teams–and they can view the progress and status of all mechanical variation management studies at any time.

Meet the Sigmetrix Customers Removing Roadblocks to Shared Product and Process Knowledge

Align the Enterprise With Shared Tolerance Stacking and GD&T Software

Bring the entire team together in the digital environments that allow you to benchmark your mechanical variation management progress against competitors and introduce all departments to a shared language and understanding.

No wasting time with choppy communication and missing information. Just operational efficiency and smoother processes.

How Sigmetrix Helps Across the Enterprise

Save time, improve profitability, innovate more, and maximize return on your investments across the enterprise.

Discover Expert Views on Product and Process Best Practices

Discover helpful resources on our blog.