Sigmetrix CETOL 6σ v11.3.0 3D Tolerance Analysis Software is Available

CETOL 6σ v11.3.0 tolerance analysis software can define simple auxiliary features, manage ignored messages, & has an updated analyzer interface.

MCKINNEY, Texas – November 22, 2022 – Sigmetrix, experts in mechanical variation management, announced their latest version of CETOL 6σ tolerance analysis software, version 11.3.0, is now available for immediate download. Tolerance analysis benefits businesses in many ways. It helps improve profitability by balancing quality with manufacturing cost. Companies can also realize faster time to market by reducing the need for additional design and prototype cycles. Finally, it allows companies to gain confidence in their product and process decisions before making costly investments.

MCKINNEY, Texas – November 22, 2022 – Sigmetrix, experts in mechanical variation management, announced their latest version of CETOL 6σ tolerance analysis software, version 11.3.0, is now available for immediate download. Tolerance analysis benefits businesses in many ways. It helps improve profitability by balancing quality with manufacturing cost. Companies can also realize faster time to market by reducing the need for additional design and prototype cycles. Finally, it allows companies to gain confidence in their product and process decisions before making costly investments.

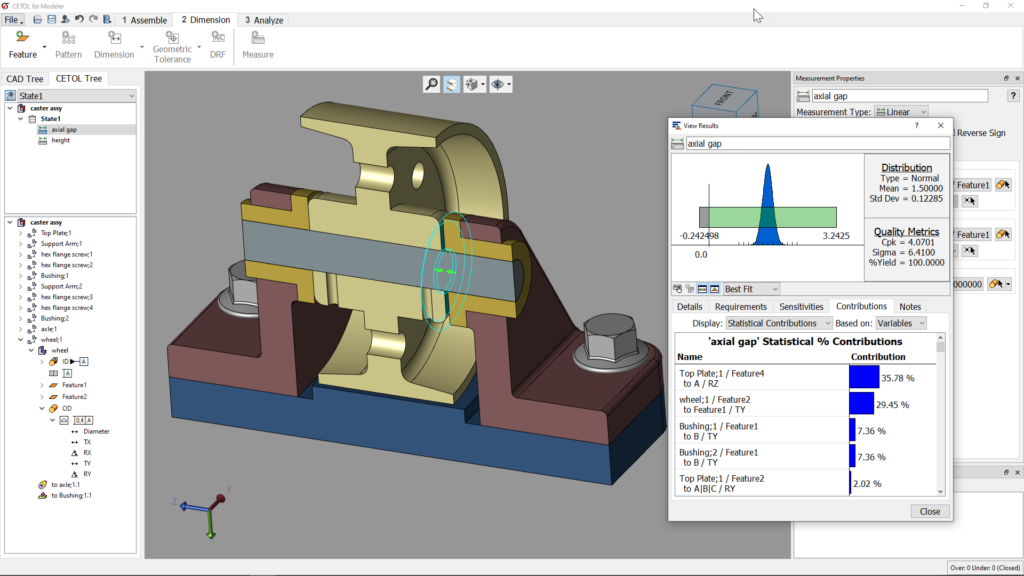

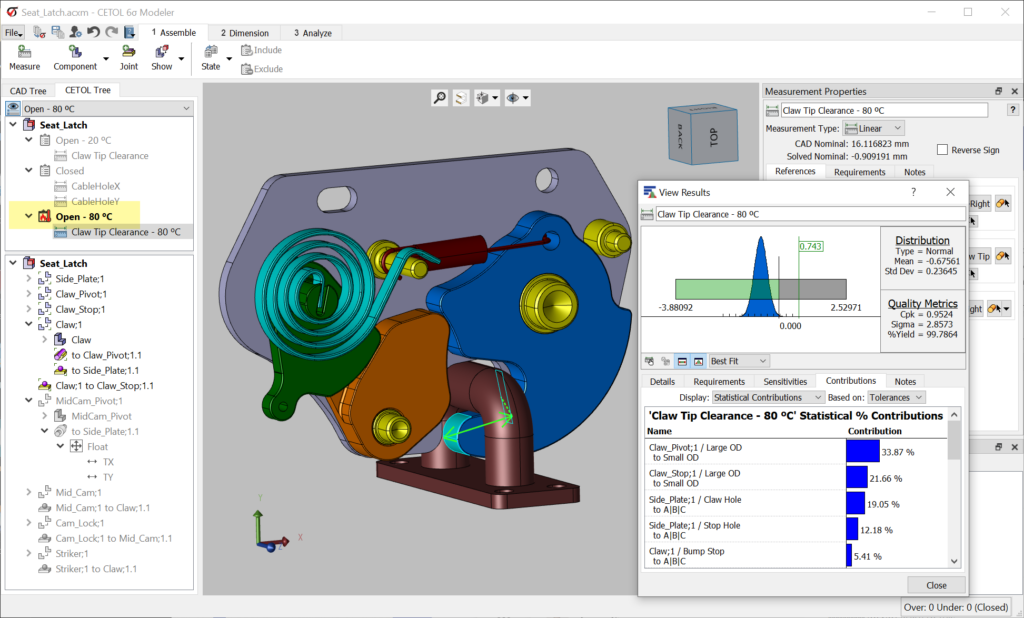

CETOL 6σ enables product development teams to easily and fully understand the often-complex impact of dimensional and assembly variation on their designs. This knowledge enables them to make the proper adjustments before problems appear in manufacturing or, even worse, in their customers’ hands. Users of all expertise levels will appreciate the multiple levels of assistance available within the software. This new version of CETOL 6σ builds upon the powerful features already in place and adds many improvements, including:

Usability Improvements:

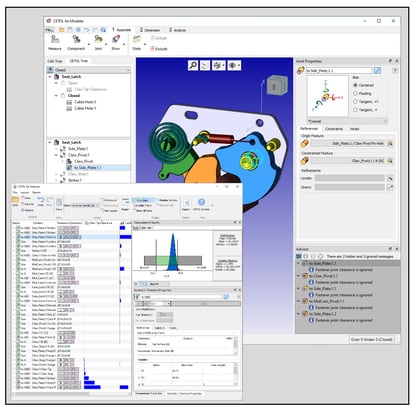

- Manage Advisor Messages that Don’t Impact the Model – Large CETOL 6σ models often have several messages in the Advisor that don’t impact the analysis. Users may now opt to “ignore” such messages, placing them in a separate area of the Advisor and permitting the user to review other messages that may require modification. This workflow enables an empty list of messages in the Advisor, avoiding concern by others during design reviews regarding the presence of the messages that don’t impact the analysis.

- Improved Analyzer User Interface – The Analyzer user interface has been significantly updated in many areas to improve overall usability and consistency with the modeler interface:

- A command ribbon replaces the toolbar

- The menus have been simplified and reorganized

- The window layout is improved and more flexible

- The properties and results views are consistent with the Modeler user interface

Improved Support for Model-Based Definition (MBD):

- Automatically Create CETOL 6σ Joints from CATIA Assembly Constraint Definitions – CATIA users may opt to have CETOL 6σ “import” CATIA assembly constraints for the automatic definition of CETOL 6σ joints. Several workflows permit the user to validate the constraints before import. This is the same functionality that has been available in the Creo and SOLIDWORKS versions of CETOL 6σ.

- Expanded Support for Common Datums (i.e. B-C) – CETOL 6σ v11.3 now directly supports Common Datums referencing parallel but not necessarily coaxial axes of cylinders and drafted cylinders (i.e. cones). Previous versions required the axes to be coaxial.

Data Management Improvements:

- Reduce the Need to Change Source CAD Models by Supporting the Creation of Auxiliary Features Directly Within CETOL 6σ – Users often need to use auxiliary geometry, such as reference planes and points, within the CETOL model. Previous versions of CETOL 6σ required defining the necessary geometry in the CAD model. CETOL 6σ v11.3 supports the creation of such features directly in the application, including:

- Points

- Lines/Axes

- Planes

- Cylindrical Surfaces

- Width Features of Size (i.e. slots and tabs)

- Automatically Save Data to a Backup File – Users may now opt to save a backup file either when saving the data to the primary location or periodically at regular, configurable intervals.

As with prior releases, CETOL 6σ v11.3.0 is available in English, Japanese, and Simplified Chinese.

Sigmetrix President and CEO, James Stoddard states, “we are excited to release CETOL 11.3 to the market.” “With the many customers requested enhancements we feel confident that companies will see improvements in their journey to build better products through mechanical variation management.”

Sigmetrix provides a complete portfolio helping customers design and produce better products through mechanical variation management. In addition to CETOL 6σ, Sigmetrix offers an array of software and training solutions including:

- EZtol, a 1D analysis tool that works directly with your CAD models, including embedded tolerances (PMI), to make it easier to create, manage, and report upon multiple 1D tolerance analyses, or stackups, in an assembly

- GD&T Advisor, an interactive tool that provides expert guidance on the correct application of GD&T withing the PTC Creo environment

- Training on a variety of topics including GD&T, tolerance analysis, dimensional management, and MBD / MBE

- Computer-Based Training on either an individual or enterprise basis developed to make learning at your own pace easy and intuitive.

- Consulting and implementation services team with years of experience in tolerance analysis and GD&T definition offers a variety of consulting services to augment your team, speed your project along and run analyses for your assemblies

CETOL 6σ v11.3.0 is available immediately for current users at: https://sigmetrix.flexnetoperations.com

For more details on the capabilities of CETOL 6σ, visit https://www.sigmetrix.com/software/cetol.

About Sigmetrix

Sigmetrix has been helping companies produce better products for over 20 years through a combination of software solutions, training, and consulting services that focus on managing the impact of mechanical variation. For more information, visit their website at www.sigmetrix.com.