Better Products Through Mechanical Variation Management

Our geometric dimensioning and tolerance analysis solutions and training help create more innovative products and efficient processes. The result? Improved profitability across the entire enterprise.

Meet Your Expert Mechanical Variation Management Partner

Sigmetrix is a global leader in dimensioning and tolerancing solutions. We support the entire enterprise from product design and manufacturing, to inspection and assembly. Our promise to our customers over the last 30+ years is simple: We provide solutions to help you create better products.

OUR SOLUTIONS-BASED SOFTWARE

Build Better Products with Our Solutions

Our Tolerance Analysis and GD&T Solutions

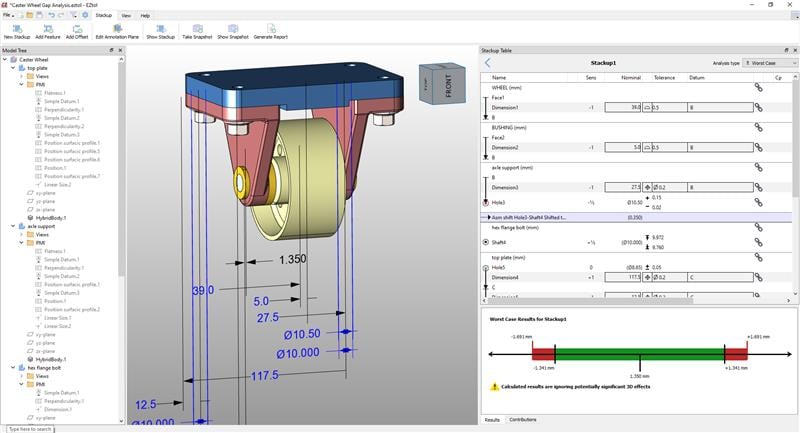

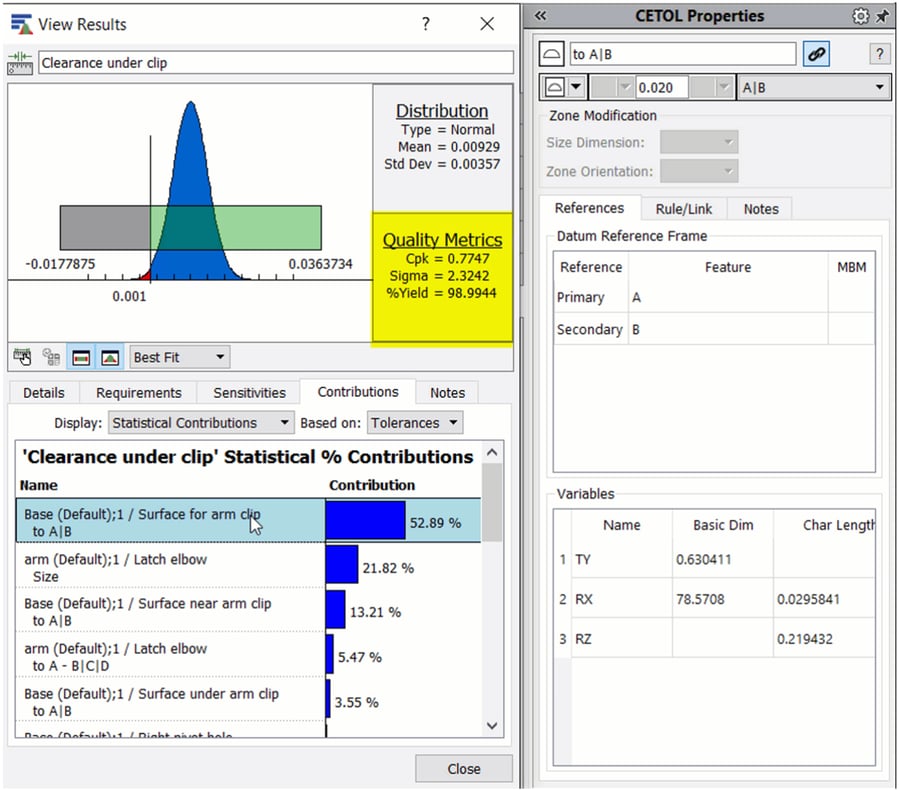

Our comprehensive, easy-to-use solutions are trusted by product design, manufacturing, system engineering, quality, and supplier relations teams to help identify mechanical variation faster, resulting in more efficient processes and more cost-effective products. Our GD&T authoring, tolerance stack-up, and tolerance analysis solutions integrate directly with major CAD systems, which make it easier for non-experts to perform tolerance stack-ups.

Resources to Help You Master Mechanical Variation Management

Get case studies, whitepapers, and more resources backed by our tolerance analysis and GD&T experts. Learn exactly how you can produce better products, reduce development costs, and make your processes more efficient.

WHO WE HELP

Variation Management Solutions for Manufacturers, Engineers, and Product Developers Across Industries

.png?width=55&height=56&name=SIG_Homepage_Images%20(5).png)

Aerospace & Defense

In an industry defined by regulations, strict product quality guidelines and trust from the consumer for safety, Sigmetrix helps meet the goals defined for a product while delivering higher-quality and safer results.

Automotive

Top automotive manufacturers trust Sigmetrix to help their products adhere to strict safety and quality standards while lowering time to market and driving down costs.

Electronics & Communication

Consumers rely on quality products that will last and function as-needed. In a world dominated by competition, Sigmetrix helps companies stand out among consumers by ensuring specifications are met, maximizing quality while reducing time to market.

Electric Generation Distribution

Production flexibility and failure reduction are hard to achieve when manufacturing products with complex variation data. Sigmetrix visualizes and simplifies variation data to provide key analytics, helping to capture and share critical information that reduces waste while increasing product flexibility.

Med Dev Pharma

Medical devices must meet rigorous safety and regulatory requirements. Sigmetrix helps meet those requirements by reducing mechanical variation, making products safer while increasing quality and lowering cost.

HVAC & Appliances

Brand recognition is built by providing high-quality products that consumers can rely on every day, at a cost they can afford. Sigmetrix helps meet production goals by managing mechanical variation, increasing quality while reducing cost.

Pumps & Compressors

When it comes to moving fluids and gas, relying on the tools being utilized to perform their job is critical. Sigmetrix allows worst-case scenario simulations, gap analyses and more key metrics before a design is ever sent to production, ensuring that the final product meets the required standards.

Expert-Led Tolerance Analysis and Geometric Dimensioning and Tolerancing Training

Sigmetrix offers a variety of tolerance analysis, GD&T, and product-focused training for users across the entire enterprise. Our trainings facilitate your unique environment, needs, goals, and users across the company. We offer comprehensive in-person or virtual software training for our flagship CETOL, EZtol, and GD&T solutions, ensuring customers are using the products to their full extent to maximize user buy-in and ROI. We also offer self-paced, computer-based training covering everything from our software to GD&T and GPS, even model-based enterprise, teaching the fundamentals of tolerance analysis first to help lay the foundation for advanced learning. Entry-level courses facilitate user onboarding, with advanced courses and topics available for additional in-depth dives on topics.

Build Better Products with Mechanical Variation Consulting

Sigmetrix is dedicated to helping our customers build better products—and that starts with a better understanding of how mechanical variation impacts their designs. We offer expert-led tolerance analysis and GD&T consulting with our senior application engineers to help identify sources of variation, achieve functional requirements during manufacturing and assembly, assist with highly complex design analysis, evaluate models for GD&T compliance, and more.

Take It From Companies Like Yours

Top manufacturers, engineers, product designers, and executives trust Sigmetrix to help them build better products. But don’t just take it from us—here’s what they have to say.

"The products of FN Manufacturing Inc. typically experience a long market life cycle. Employing CETOL in conjunction with our [design] database, we can analyze our mature product lines to allow optimization of the existing tolerances."

Vice President, Engineering

Aerospace & Defense Manufacturer

"We chose Sigmetrix because of their subject expertise and long history of successful mechanical engineering products."

Executive

Automotive Parts & Accessories Manufacturer

"The caster part of an operating room bed was having problems. The break system alignment, regardless of tire alignment, is a complex mechanism requiring precise tolerance. CETOL was used to optimize the dimensions and tolerance and improve performance."

Executive

Medical Device Manufacturer

Scrap the Waste. Improve Your Bottom Line.

Sigmetrix has 25+ years of experience helping customers identify mechanical variation issues, resulting in more innovative products and cost-effective processes. Let’s talk about how we can help you realize these results with our tolerance analysis and GD&T software and solutions.